I'll be using the kitchen oven to heat the plastic, so I only needed to make the vacuum table. The table is actually a box that hooks up to my shop vac, so it sucks the softened plastic down. It's 2' square, with a pegboard top, 1x2 sides, and plywood for the bottom. The legs are 2' 2x4s.

I found a PVC fitting that fits my shop vac hose perfectly. It's some kind of reducer that I just adhered with caulk over a hole in the middle of the plywood.

It hooks up like this.

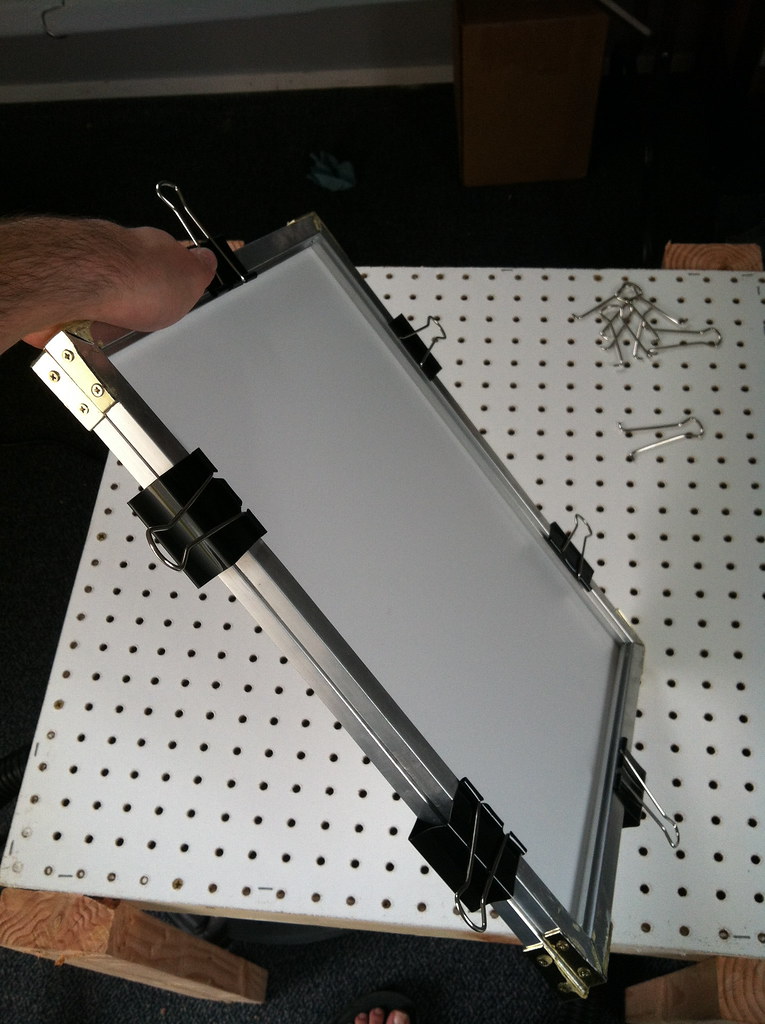

These are the frames that will hold the plastic. Aluminum window screen frame stock made into 12 x 16" frames with L brackets and Gorilla Glue for good measure. They'll get clamped on either side of the plastic sheet.

Like that.

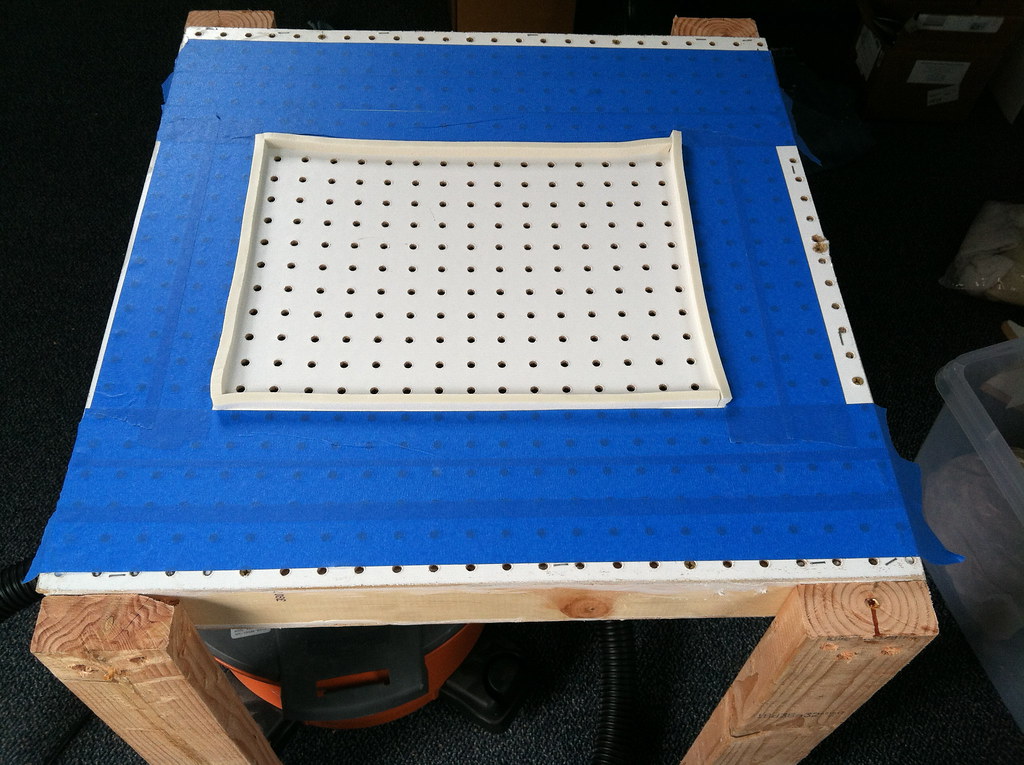

If you've been watching the numbers, you'll have noticed that my frames are smaller than my table. I'm taping off the holes in the extra area of the table. I wanted to make it bigger than I needed for future projects.

Now, I won't say what my first project with the vacuum former is yet, but I will tell you that it's related to the new projection effect. Stay tuned, because in the next few days I'll put this thing to use.

Very cool! Can't wait to see what you make

ReplyDeleteAmazing! You're so very resourceful! Can't wait to see how your first vacuum form turned out :)

ReplyDeleteNice post

ReplyDeleteVery Nice ! cute post...

ReplyDeletepvc box machine