Or: Jeepers Creepers, Why Are Your Peepers Moving?

You may have noticed I've got a thing for movie MacGuffins. One of my favorites has always been the golden statue from the beginning of Raiders of the Lost Arc. The stumbling points that have kept me from it are acquiring a decent casting of the real deal (they are out there), and figuring out a solution to gold plating it. But I think I got a satisfactory solution to both, so here's my process.

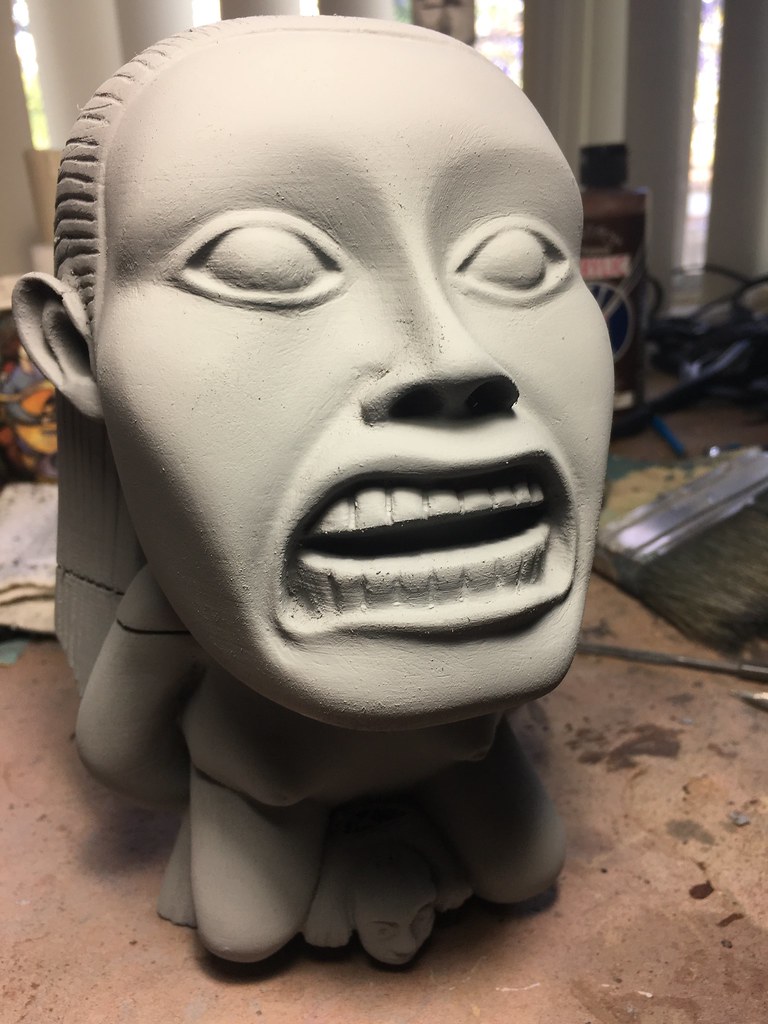

First problem solved: Someone appears to have scanned a (perhaps modified) copy of the stunt version of the idol on Thingiverse. So that's handy. The only thing is the stunt version has a different expression, and this one has some other quirks. If I were more of a digital whiz, I'd have fixed it in the 3D model, but I printed it as is and modified it after.

I like to give my PLA prints a rough sanding right off the bat.

Then a coat of filler primer

The primary issues here are the downturned corners of the mouth, the face of the baby, and the hairline.

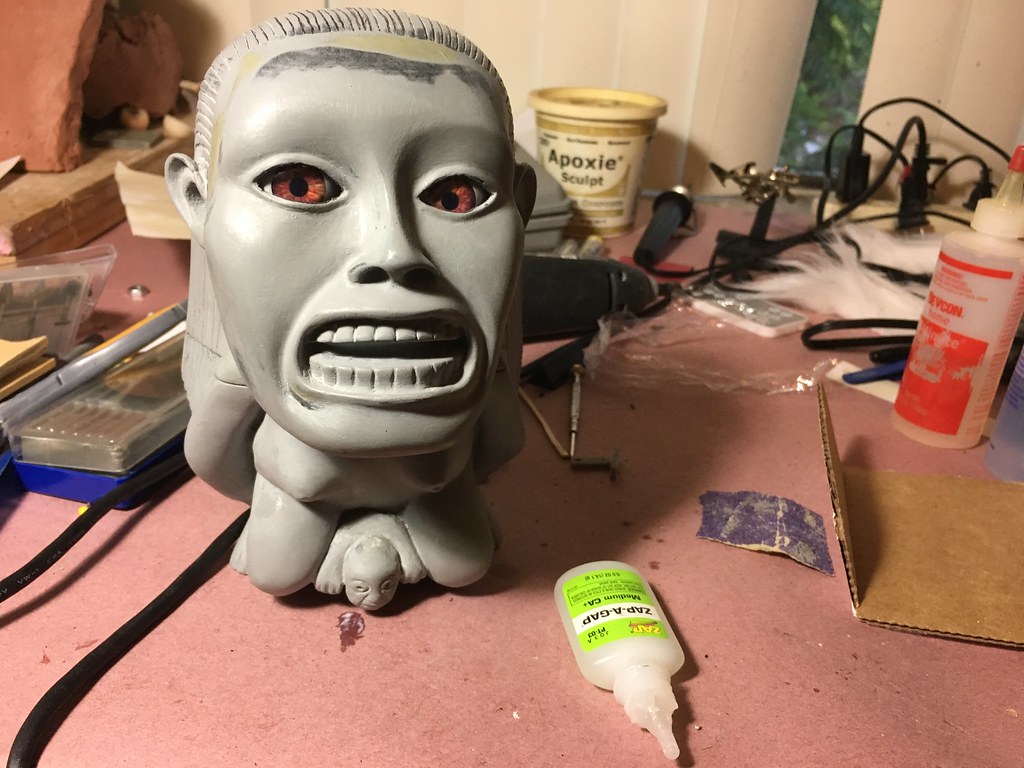

After a few passes of primer and sanding, I corrected those with Apoxie Sculpt, which is an epoxy putty that sets up in a few hours and is nicely sandable.

Now once I got this far, I figured the project might actually turn out all right, so I started thinking I might as well take it one step further. Most people have never noticed, but the eyes of the hero prop in the movie were not only glass humanlike eyes, but moved back and forth. I had to take the challenge.

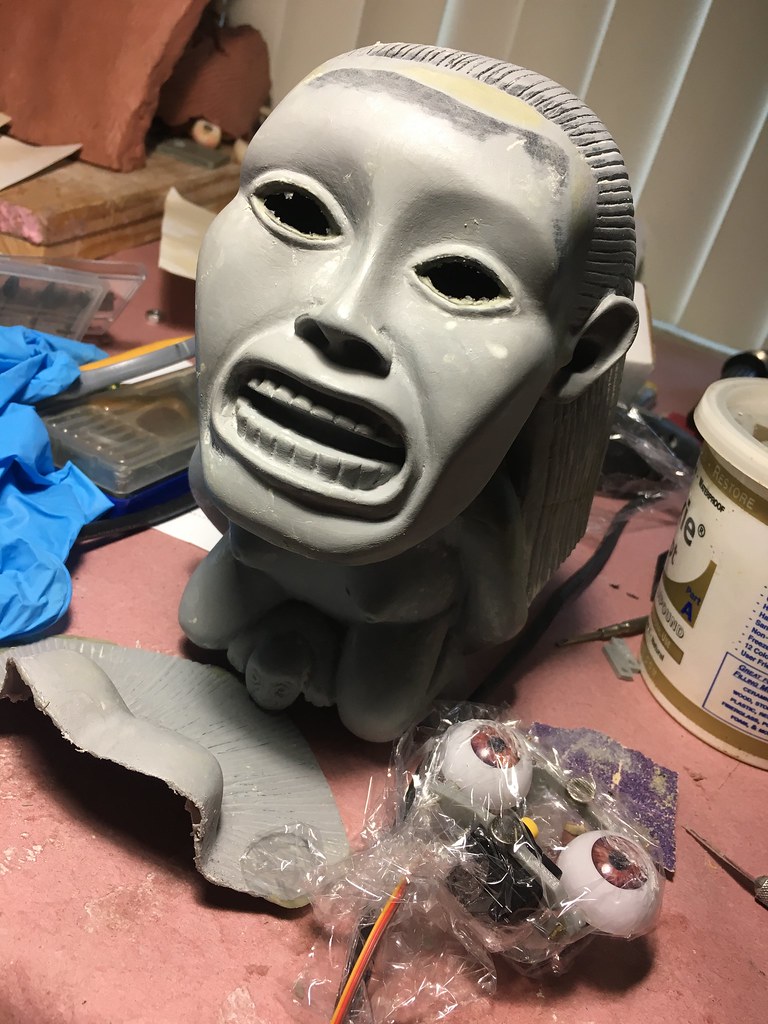

If I had planned it this way from the beginning, it might have been easier, but I didn't, so it wasn't. I had to dremel out all the support material from the inside to fit an eye mechanism.

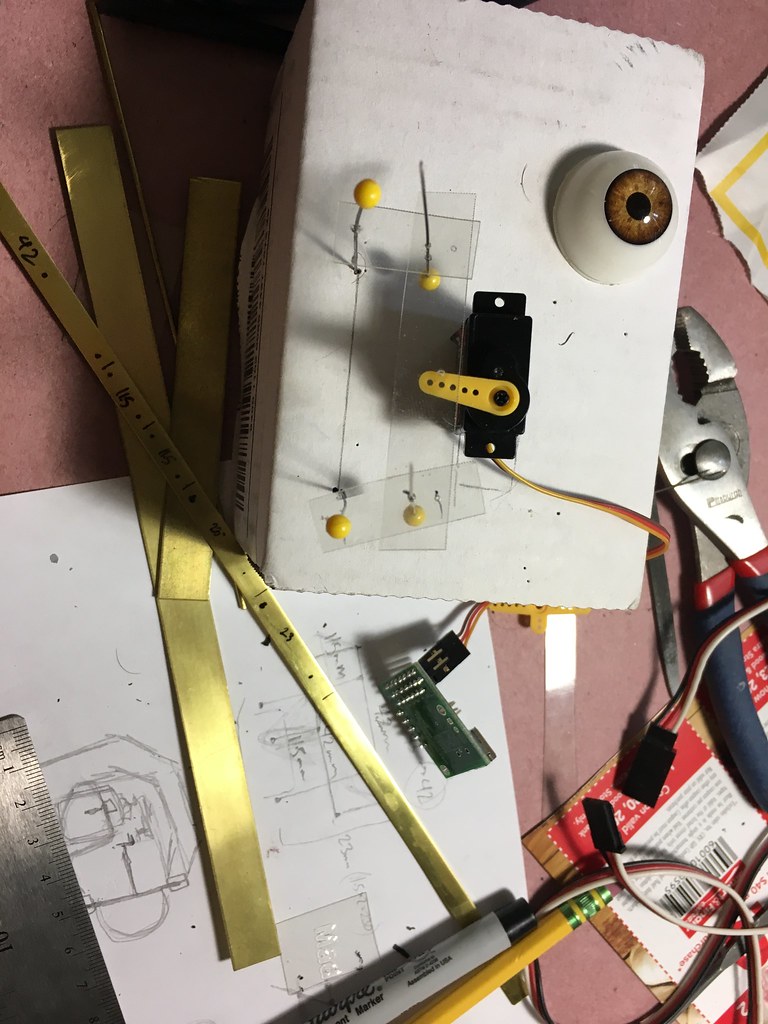

I ordered several different plastic eyes to decide what would work best. The one you see below was my favorite looking, but I ultimately decided to use another without a corneal bulge, because a totally spherical eye would be able to fit tighter to the rigid eyelids while they're moving.

I prototyped out the mechanics with some pins and scrap plastic. The actual design had the servo on the other side.

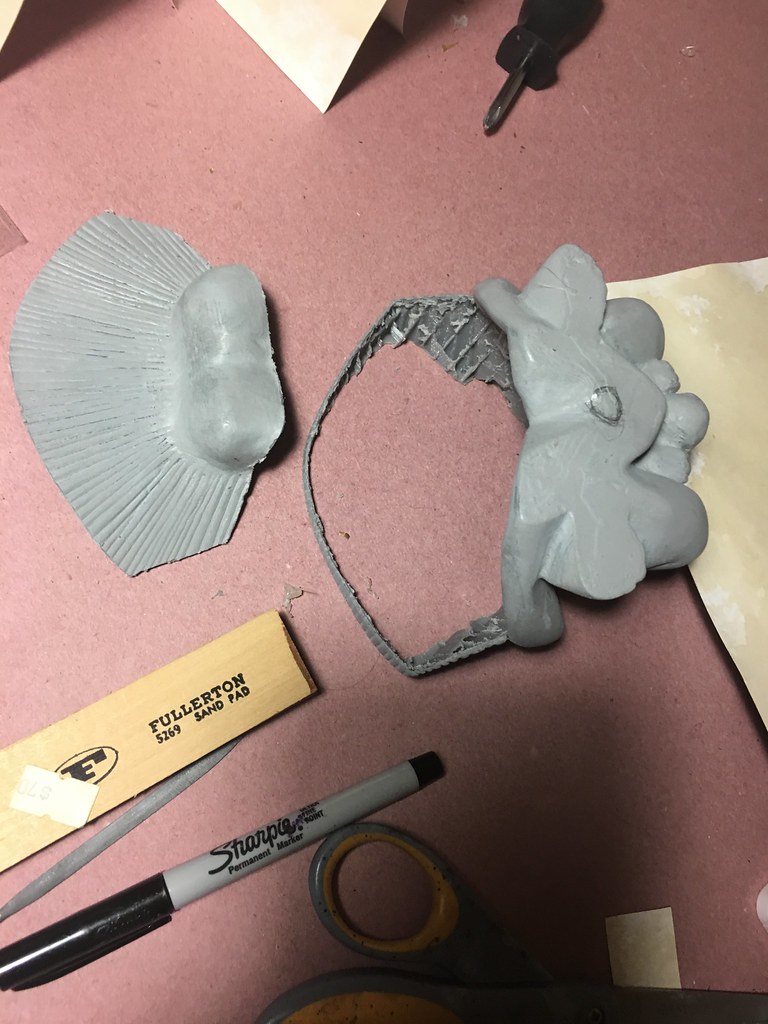

One of the puzzles I wanted to solve was the hatch to access the mechanics. The original had a somewhat awkward cut across the top of the head so the whole back of the head could come off. I wanted to avoid anything conspicuous, so I devised a door on the underside of the hair. This is where having the model in two pieces worked to my advantage, because I could have easier access to the back of the eyes to set things up initially.

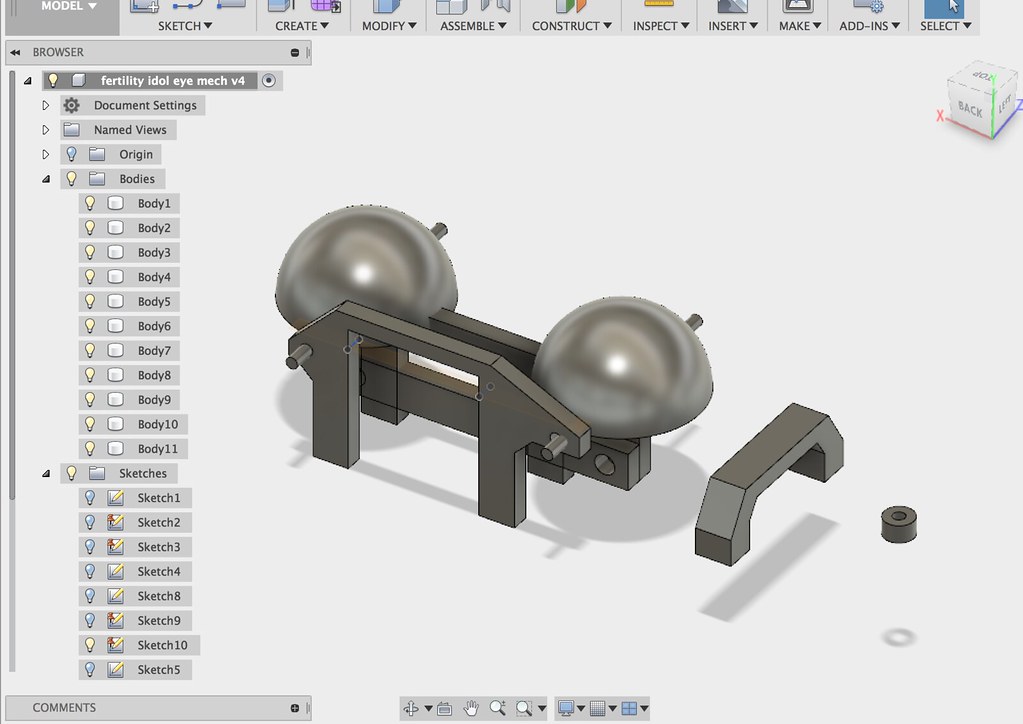

I had originally planned to build the eye mech out of brass stock, but I was inspired by the mechanical designers I've been working with at the ol' 9 to 5, and I ended up modeling the eye mech in Fusion 360 for 3D printing. The first time I built it, the eyes were just a hair too far apart to seat correctly, so I had to redo it, which is fairly trivial when the computer is doing most of the work.

When I got it how I liked it, I mounted the whole mech inside the head with magnets. There were two reasons for this. 1) I wanted to be able to easily remove the mech if needed, and 2) I wouldn't be able to get any conventional tools up there once the body was sealed up. Okay, 3 reasons. 3) I like magnets.

I 5-minute epoxied the magnets to the mechanism, and then used propoxy to mount the ones in the head, using a bit of plastic wrap as a barrier. You can see the controller board here. It's a Pololu Micro Maestro. I've become fond of these for this sort of simple animatronics control. It's small and, unlike an Arduino, is designed for smooth servo movements. The software is not as easy to program as VSA, but that's the tradeoff for being self-contained.

At this point I could superglue the two halves together.

I poured some resin in the feet to weight the bottom so it would be a little less top heavy.

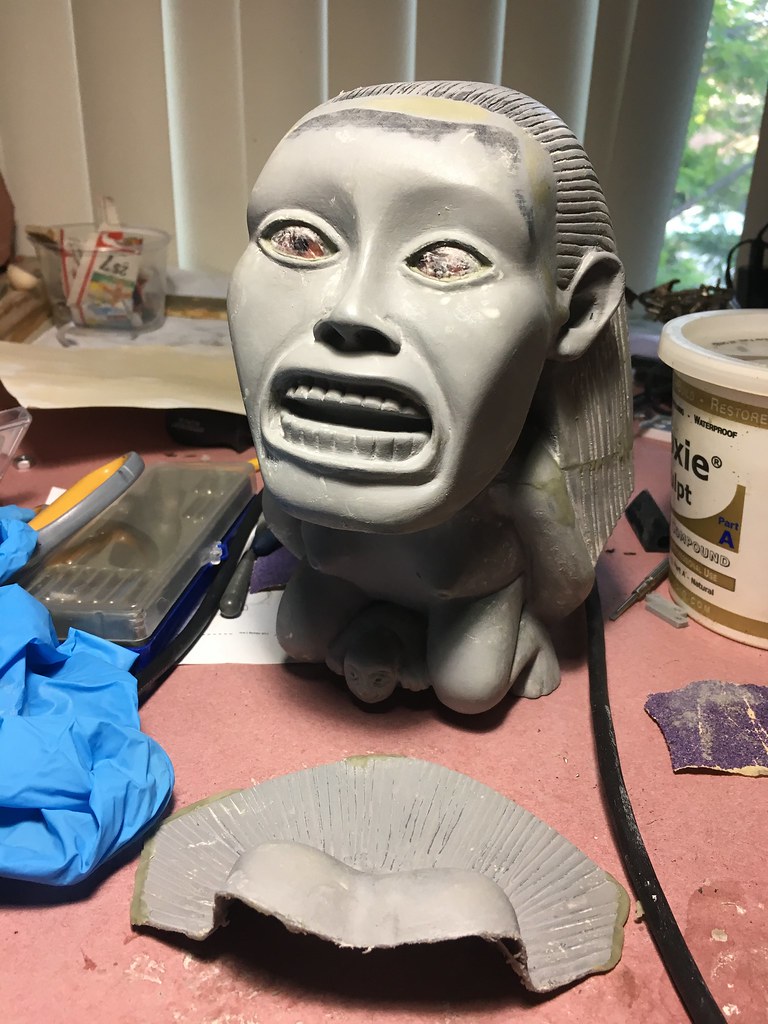

The eyelids needed a little resculpting to fit cleanly around the eyeballs. I wrapped them in plastic wrap before inserting them back into the head, and using Apoxie Sculpt to fix them up.

I also worked on the seam between the two parts, and the join on the trap door.

Nothing's a one step process. You can see even here there are print layers that can be seen and seams that need another pass of patching.

That hair took a lot of going over with a small, triangular file (thanks, Harbor Freight).

When I finished bodyshopping, I went into glossing it up. I decided at this point that I could get it chrome-enough with Alclad chrome model paint. As for the gold color, well, one step at a time. Now, I've always been told to do chrome paint over a black glossy base. The problem I've had with that is that you can't go too heavy with the Alclad, or it loses the reflectivity, so there's always sort of a darkness to the chrome from the black base. I went ahead with just three coats of gloss clear on the assumption that a glossy grey would lead to a brighter silver.

There were a few spots where I had sanded down to the black PLA before clear coating, and sure enough, I could see those through the chrome as darker chrome areas, so the grey experiment worked. The other bonus of a grey under layer is that, should the chrome rub away (and Alclad will tend to do that, though I've started applying it before the clear coat is totally dry to help it grab hold), a little exposed grey won't draw nearly the attention of a black spot.

So then I started figuring out how I'd tint it. The tricky thing is that most clear coats disrupt the reflectivity of the Alclad. I think it has to do with solvents causing the tiny metal flakes to shift out of alignment and/or not allowing light to pass straight through.

There's a "golden yellow" candy color that Alclad sells, but I found it to be too strongly pigmented for this. Eventually I stumbled upon a video by Gordon Tarpley, in which he suggested Liquitex Gloss Varnish (I used High Gloss) mixed with food coloring. Airbrushing this gave the best results in my small scale tests, so I went for it.

On the actual prop, however, the varnish would dry in one spot before I could get the whole peice wet, which meant it wouldn't level out smooth unless I really flooded it, and I didn't want to do that because more paint meant more intense color, so I ended up doing a top coat of just the varnish to bring back the shine. I did get some drips (which surprisingly don't show up much in the picture above), but I planned to do some weathering, and I figured I could just cover up the drips then.

I followed that up with a weathering pass of a few shades of acrylic sparingly stippled on with a chip brush.

Now, the end result is definitely not chrome gold, but it's surprisingly convincing as polished metal in person. I think the weathering pass gives a matte contrast to the gold that sells it. And the hatch in the bottom is barely noticeable when on battery power. If I want to run it off wall power, the cord can fit neatly in the slight gap at the bottom of the hatch.

Oh, and it does this.