On to Phase 2: Molding and Casting!

So, I glued the sculpture to an 18" tile to prepare for molding (typically people use melamine board, but I couldn't find any a reasonable size, and this was only a couple bucks). A gave it three coats of clear spray paint, and one pass of Ultra 4 Epoxy Parfilm, a release agent that is paintable, meaning it won't leave residue on the mold (and later, when I use it in the mold to release the castings, it won't leave residue on the castings, so I can paint on them without having to clean off an oily release).

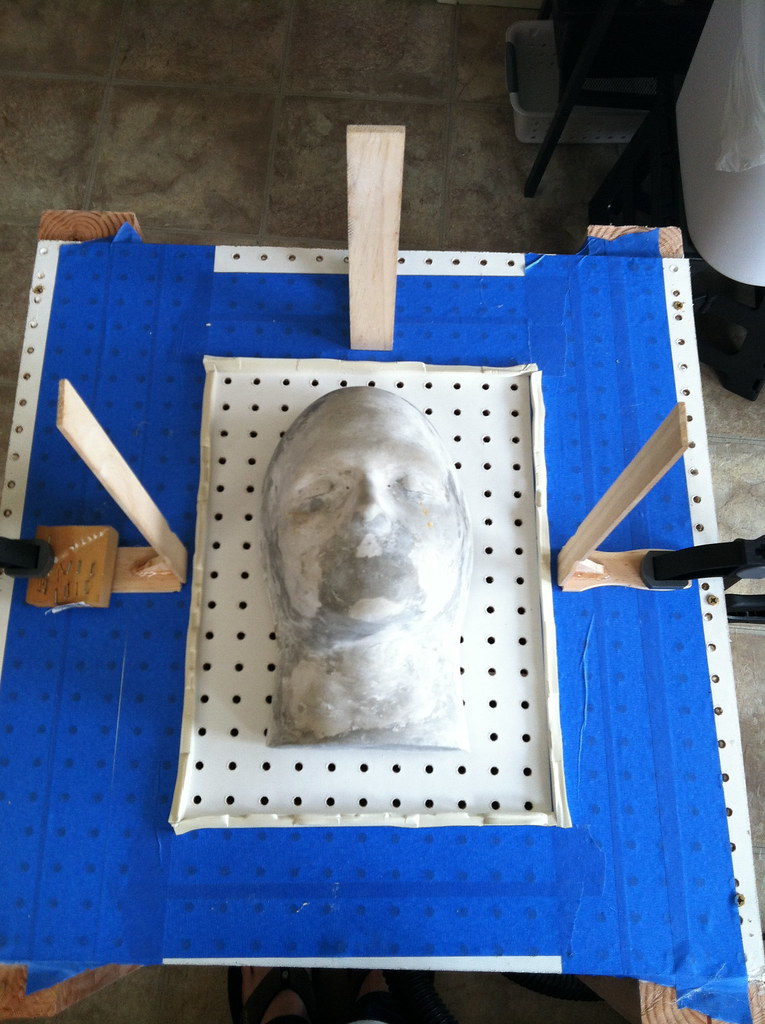

Then I went in with silicone. The plan is to do enough silicone to cover the piece and fill in undercuts, then back that up with a rigid shell to hold its shape. This silicone is Mold Max 30 from Smooth On. It seems to be working pretty well, and it's a bit cheaper than the stuff that I usually use. Plus it's so pink and pretty! :P

That was the first layer, brushed on thin to get the surface details.

I went in with several more layers until all the undercuts of the sculpture were filled in. These layers I added a thixotropic agent to (Thi-vex, from Smooth On). This makes it more paste-like, so I can put on a thicker layer without it dripping so much. There are brushable silicones you can buy, but adding the "thixo" means I only have to buy one kind of silicone, and I can modify it to do different things. In total there are about 1.5 quarts of silicone on this.

You'll also notice some rectangles on there. I made those ahead of time and stuck them on to act as keys, so the silicone would register in the right spot in the hard shell later.

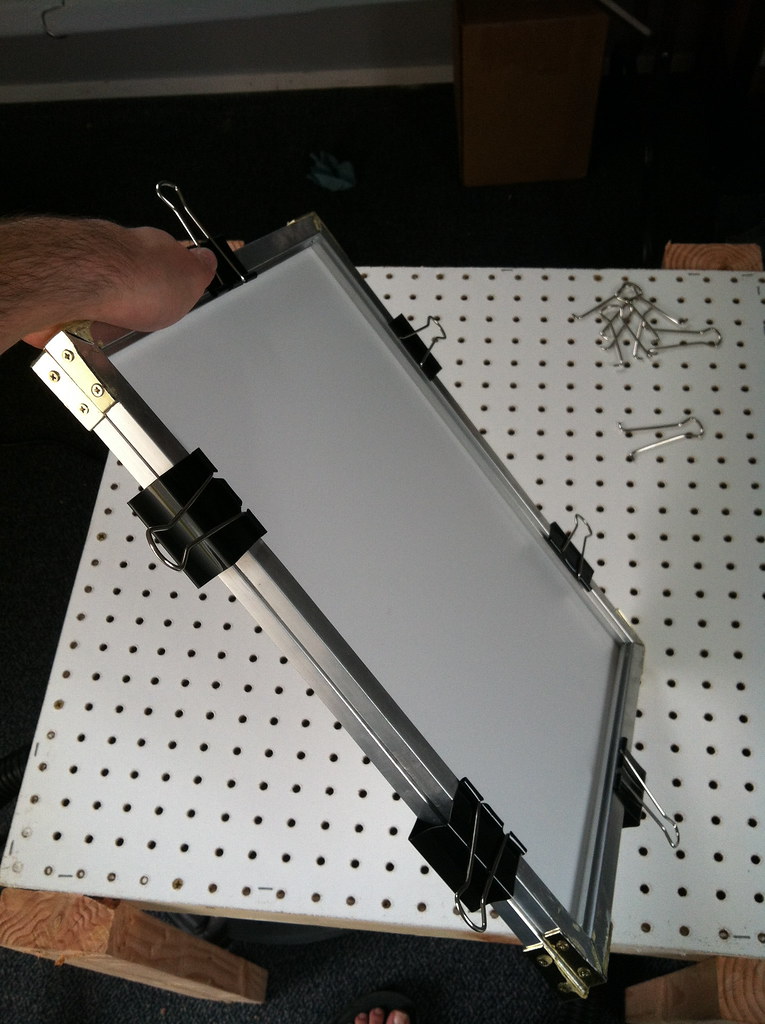

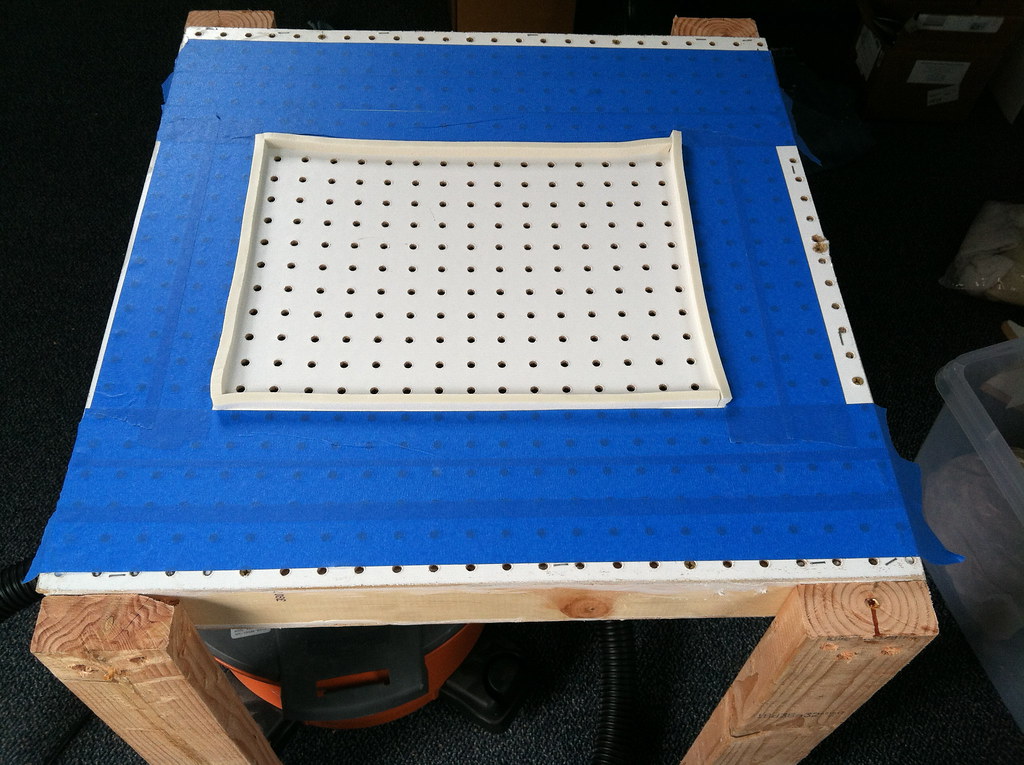

The shell is just two layers of burlap dipped in ultracal:

And when everything was set and cured, I demolded!

Into the mold, after a few passes of parfilm, I brushed a 2-part expanding rigid polyfoam. I only need enough to make the thing hold its shape, and the weight of the globe.

Once THAT set, I demolded to find a pretty darn good first casting.

A bit of gold, a bit of black, and a nice big acrylic globe on top, and there we go! Here's Sybil's new crystal ball home.

I might still give it a gloss coat...we'll see.

Now, you might be wondering why there's a big ugly hole in the middle of the base, when her head would fit perfectly right on the flat surface that I sculpted. I'm not telling. Not yet. But the reason is really cool, if I do say so myself. ;)